What

is a canned cycle?

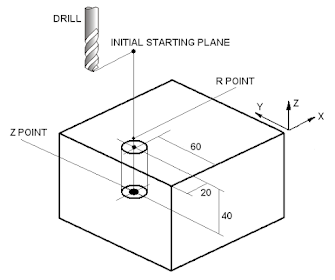

Canned cycles are commonly

used to simplify complicated machining operation programming. Different canned

cycles are typically applied for repetitive machining tasks such as drilling,

boring, and tapping. They are selected or activated using various G-codes and canceled

using the G80 code. In a canned cycle, the X and Y-axis movements are executed

with a Rapid command, while the Z-axis motion is controlled with the Feed

command. Canned cycles help reduce program memory since fewer blocks are

required compared to non-canned cycle programming. The following parameters are

typically used in simple canned cycle programming:

X

& Y – Hole position

data

Z –

Distance from point ‘R’

to the bottom of the hole

R –

Retract plane

Q –

Depth of cut for each

cutting feed

F – Cutting feed rate

K – Number of repeats

1. Drilling

Cycle (G81)

N5

T1 M06 (Drilling

tool changing)

N10

G00 G90 G54 X20 Y60 (Positioning

over the drilling point with zero offsets)

N15

M03 S2000 (Spindle ON)

N20

G00 G43 H01 Z1 M07 (Rapid positioning

Z-axis with tool offset)

N25

G81 G99 Z-41 R1 F10 (Drilling cycle on

& returning to R point after completion)

N30

G80 G28 X0 Y0 Z0 (Cancelling canned

cycle and returning home position)

N35

M05 M09 (Spindle stop

& Coolant off)

N40

M30 (End

of the program)

2. Peck Drilling Cycle (G83)

N5

T2 M06 (Drilling

tool changing)

N10

G00 G90 G54 X20 Y60 (Positioning

over the drilling point with zero offsets)

N15

M03 S2000 (Spindle

ON)

N20

G00 G43 H01 Z1 M07 (Rapid

positioning Z-axis with tool offset)

N25

G83 G99 Z-61 Q20 R1 F10 (Peck

drilling cycle on & returning to R point)

N30

G80 G28 X0 Y0 Z0 (Cancelling

canned cycle and returning home position)

N35

M05 M09 (Spindle

stop & Coolant off)

N40

M30 (End

of the program)

3. Tapping

Cycle (G84)

N5

T3 M06 (Tapping

tool changing)

N10

G00 G90 G54 X20 Y60 (Positioning

over the drilling point with zero offsets)

N15

S200 (M03

not required, as G84 will turn ON the spindle)

N20

G00 G43 H01 Z1 M07 (Rapid positioning

Z-axis with tool offset)

N25

G84 G99 Z-41 R1 F10 (Tapping cycle on

& returning to R point after completion)

N30

G80 G28 X0 Y0 Z0 (Cancelling canned

cycle and returning home position)

N35

M05 M09 (Spindle stop

& Coolant off)

N40

M30 (End

of the program)

4. Bore

in & Bore out canned cycle (G85)

N10

G00 G90 G54 X20 Y60 (Positioning

over the drilling point with zero offsets)

N15

M03 S1000 (Spindle ON)

N20

G00 G43 H01 Z1 M07 (Rapid positioning

Z-axis with tool offset)

N25

G85 G99 Z-41 R1 F10 (Boring cycle on

& returning to R point after completion)

N30

G80 G28 X0 Y0 Z0 (Cancelling canned

cycle and returning home position)

N35

M05 M09 (Spindle

stop & Coolant off)

N40

M30 (End

of the program)

No comments:

Post a Comment