What is an axis?

The axis of a CNC machine refers to the arrangement that enables relative movements between the cutting tool and workpiece. These movements can occur between the workpiece and a stationary cutting tool, the cutting tool and the workpiece, or both can have relative movements. CNC machines commonly have two types of axes: linear and rotary. Linear axes facilitate horizontal and vertical movements, while rotary axes follow circular paths. Servo motors are typically used for axis movements in CNC machines. The images below depict a linear and rotary axis.

Naming of axes

A CNC machine may have two,

three, or more axes. However, the primary axes of the machine, which form the

XYZ coordinates of the 3D coordinate system, are X, Y, and Z. The naming of the X,

Y, and Z axes always follows the right-hand rule. The images below illustrate

the naming procedure for the three primary axes of a vertical milling machine

and their relation to the coordinate system.

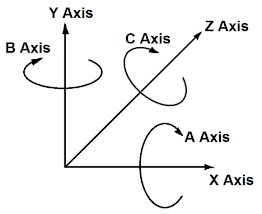

In this case, the X-axis movement is horizontal and parallel to the workpiece table. Similarly, the Z-axis movement is parallel to the spindle and aligned with the cutting tool, while the Y-axis motion is perpendicular to the X and Z axes (see the picture). The same right-hand rule applies to horizontal or vertical milling and turning machines. A CNC machine may also be equipped with a rotary axis. When the rotary axis moves in line with the X-axis, it is referred to as the A-axis; in line with the Y-axis, it is the B-axis, and along with the Z-axis, it is called the C-axis. The following picture illustrates the names of different rotary axes in a CNC machine.

Some advanced CNC machines may also have additional linear axes, increasing the flexibility of machining or manufacturing procedures. U, V, and W axes are considered supplementary linear axes. The linear axis parallel to the X-axis is called the U-axis, the one parallel to the Y-axis is known as the V-axis, and the axis parallel to the Z-axis is referred to as the W-axis. The use of additional axes with CNC machines is limited. The following picture shows a multi-axis CNC machine with rotational axes and an auxiliary U-axis.

Types of CNC machine

Before starting a machining

program, it is crucial to understand the machine's architecture, such as the

type of machine (turning or milling), the number and names of axes present, and

the movement directions (positive and negative). This knowledge is also

essential for selecting horizontal or vertical machining for milling

operations. Different CNC machines are used for various machining or metal-cutting operations. Machining centers (horizontal or vertical) are commonly

employed for milling operations while turning centers are used for turning

operations. The following pictures depict three types of CNC machines and their

standard axes configuration with movement directions, commonly found in modern

machining industries.

In a horizontal machining center, as shown in the first picture, the spindle is aligned with the Y-axis and moves vertically (upward and downward), while the X and Z axes move horizontally in positive and negative directions. In a vertical milling machine, the Z-axis moves vertically, and the spindle is associated with it (see the second picture), while the horizontal motion is related to both the X and Y axes. In a turning center, the spindle rotates in a fixed position with a workpiece, and the cutting tool is attached to a turret unit that moves along the X and Z axes. Most CNC turning centers have only two axes (X and Z), although some special-purpose CNC turning centers are sometimes equipped with the Y-axis.

Sometimes CNC machines also incorporate a rotary axis to increase flexibility in machining. In a horizontal machining center, the rotary axis is referred to as the B-axis, while in a vertical machining center, it is termed the C-axis. The naming procedure for different axes in CNC machines was discussed earlier. The following picture shows the rotary axis and the movement directions of different axes in a horizontal machining center.

No comments:

Post a Comment