Limit switch:

A limit switch is a simple digital contact-type sensor

commonly used in various mechatronics systems to send position signals of a

moving appliance. Typically, a limit switch provides two types of signal

outputs: Normally Closed (NC) and Normally Open (NO). The picture below shows

the internal view of a general type of limit switch.

The limit switch usually

consists of a mechanical plunger that can move against spring tension. By

applying force to the top of the plunger, it is pushed downward and returns to

its original position when the pressure is released. A small snap switch is attached

to the plunger and activates or deactivates based on the plunger movement. The

snap switch used inside the limit switch is a special type that includes a tiny

plunger on top of the switch with a movable contact. This contact changes its

position between two fixed contact points, exerting slight pressure on the

plunger. In the normal state, the movable contact always connects to one fixed

contact point, and when the plunger is pressed, it changes position and

connects to the opposite fixed contact. The stationary contacts are normally

considered as NC, while the opposite connection is the NO contact. The pictures

depict the internal view of a snap switch operated within a limit switch.

Different types of snap

switches can be found inside a limit switch, depending on the current-carrying

capacity and plunger design. Typically, limit switches utilize micro-snap

switches with a capacity of 250 V and 5 Amperes, suitable for mechatronics

systems. Various limit switches are available, offering different designs such

as roller type, pin type, and more.

Inductive proximity sensor:

An inductive proximity

sensor is the most commonly used non-contact digital sensor in mechatronics

systems. Inductive proximity switches come in different types based on their

construction and functionality, such as NPN or PNP type, plug or cord type, and

more. However, the basic working principle remains the same for different

inductive proximity switches. The block diagram below illustrates an inductive

proximity sensor commonly found in CNC machines.

The left-side picture shows

an inductive proximity switch constructed with four components: a coil,

oscillator, trigger circuit, and output switching circuit. A coil is typically

wrapped on the head face of the proximity switch, just beneath the sensing

face. The output of the oscillator circuit is fed to the coil, creating an

alternating magnetic field in front of the switch, known as the sensing field.

This magnetic field extends outside the proximity switch through a non-metallic

lining. When a metallic object like iron, copper, aluminum, or steel comes

closer to the alternating magnetic field, it induces an eddy current within

that object. The eddy current causes a power loss in the oscillator circuit. As

the metallic object gets nearer to the proximity switch, the power loss

increases, exerting pressure on the output of the oscillator circuit and

reducing the amplitude of the oscillator output (see the right-side picture).

Once the amplitude drops below a specific threshold level, the oscillation of

the oscillator circuit stops due to the loading caused by the eddy current. At

this point, the trigger circuit detects the output of the oscillator circuit

and turns on the output switching circuit. The sensing distance of a proximity

switch indicates its capability to sense metallic objects up to a maximum

distance from the sensing face, which typically depends on the diameter of the

sensing coil. A smaller diameter inductive proximity switch has a shorter

sensing distance, while a larger one has a longer sensing distance. It's

important to note that the sensing distance of the same proximity switch may

vary with different sensing objects due to their material properties.

A proximity switch usually

has three terminals: positive (+), negative (-), and a switching output

terminal. By supplying both the positive and negative terminals (typically

using a 24 V DC supply) and sensing it externally, a 24 V DC output can be

obtained from the switching output terminal. Proximity switches are commonly available

in two types: PNP and NPN. For a PNP-type proximity switch, the switching

output is obtained with respect to the negative terminal, while for an NPN

type, it is considered with respect to the positive terminal (as shown in the

earlier pictures). Sometimes, a single proximity switch can provide both

Normally Closed (NC) and Normally Open (NO) switching outputs, resulting in

four terminals. An LED is typically included to indicate whether the proximity

switch is sensing or not.

Capacitive proximity sensor:

A capacitive proximity

sensor is another type of non-contact digital sensor used to sense non-metallic

objects and, occasionally, liquid levels. Capacitive proximity sensors or

switches can be categorized into two types: dielectric and conductive. Inside a

capacitive proximity switch, two plates are positioned in front of the sensing

surface, and the sensing object acts as a dielectric between these plates. When

the sensing object comes within a certain distance in front of the sensing

face, the capacitance value reaches a specific level, triggering a built-in

trigger circuit inside the switch and generating a switching output. Capacitive

proximity switches are generally more expensive than inductive proximity

switches, and their applications are limited in mechatronics systems. The

picture below shows a capacitive proximity sensor.

Infrared Sensor:

An infrared sensor is a

non-contact digital sensor used to detect opaque and non-metallic objects from

a long distance. There are three types of infrared sensors: Thru-beam type,

Diffuse reflective type, and Retro-reflective type. In mechatronics systems,

infrared sensors are commonly used to sense opaque objects from a distance. The

picture below shows a typical infrared sensor.

Thru-beam Infrared sensor -

This type of sensor consists of two separate units: an emitter and a receiver

(see the picture), both placed on opposite sides of the sensing object. The

emitter unit transmits an infrared light beam, which falls directly on the

receiver unit through a lens. If an opaque object obstructs the infrared light

beam falling on the receiver unit, a switching circuit inside it is activated,

providing the necessary sensing output. The great advantage of using this

sensor is its long sensing range, but a disadvantage is that it requires two

separate wirings for the emitter and receiver units.

Diffuse reflective Infrared

sensor - Here, the emitter and receiver are assembled in a single unit. An

infrared light beam from the emitter falls on an opaque object through a lens,

and the reflected light returns to the receiver segment, turning a switching

circuit ON or OFF depending on the presence or absence of the light beam. This

sensor is more manageable than the Thru-beam type as it uses a single unit

instead of two separate units. The sensing distance of this sensor is always

shorter than that of a Thru-beam type sensor, and it requires a bright or shiny

surface as the sensing object.

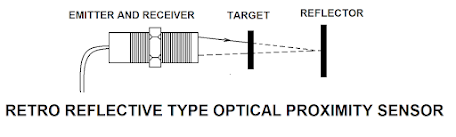

Retro-reflective Infrared

sensor - These are the most commonly used sensors in mechatronic systems

compared to the other two types. Both the emitter and receiver are assembled in

the same unit, similar to the Diffuse-reflective type sensor. A reflector is

always used with this sensor, and the infrared light beam transmitted from the

emitter is reflected directly from the reflector back to the sensor receiver.

When an opaque object appears between the reflector and sensor, the light beam

is obstructed, and the sensor turns ON an output switching circuit, indicating

the presence of an infrared light source. Operating this sensor is very

convenient in any mechatronics system as only one device is required for

wiring. The sensing distance is also very high when using a reflector. However,

this sensor cannot be used with shiny or reflective surfaces.

Pressure Sensor:

A pressure

sensor or pressure switch is a digital contact-type sensing element used to

measure the exact pressure level in hydraulic or pneumatic systems. When there

is significant pressure inside a pressure line, it activates a small 'Snap

switch' and provides a sensing output. The switching output can be either

Normally Closed (NC) or Normally Open (NO). A diaphragm or piston is typically

fitted inside a pressure switch, influenced by fluid pressure against spring

tension, and it activates the snap switch. When the fluid pressure ceases, the

snap switch plunger returns to its initial position due to spring tension. The

picture below shows a hydraulic pressure switch and its internal configuration.

A pressure switch usually has a pressure adjustment knob (see picture) to set

the required pressure for switch activation. By adjusting the innerspring

tension through a screw, the necessary fluid pressure to activate the snap

switch can be increased or decreased. Pressure switches are usually built with

different designs and sensing media or elements, such as hydraulic pressure

switches and pneumatic pressure switches, among others.

Magnetic Sensor:

A magnetic sensor, commonly

known as a magnetic reed switch, is a non-contact digital sensor that activates

in the presence of a magnetic field. It consists of two tiny and thin iron

plates positioned inside a small glass container, with a small gap between

them. When a permanent magnet approaches the glass bulb, one of the inner

plates bends and connects to the other, acting as an electric switch. The

electrical contact is disconnected when the magnet moves away, returning the

plates to their original position. Switching contacts can be of either Normally

Open (NO) or Normally Closed (NC) types and are usually integrated into the

mechatronic system's magnetic sensor. The picture below shows how a 'Normally

Open' type magnetic sensor works.

Level Sensor or Float

Switch:

A level sensor or float

switch is a digital contact sensor used to measure the liquid level or height.

Most float switches work based on the buoyancy principle. A float is typically

set inside a float switch, which hovers on the liquid surface and swings upward

and downward depending on the liquid level. There is a small magnet inside the

float (see the picture), which turns ON or OFF a magnetic reed switch. The

magnetic reed switch is positioned inside a tube made of non-magnetic material,

allowing the floated magnet to activate the reed switch only when the float

reaches a specific position. As a result, the reed switch inside the float

switch only activates when the liquid level reaches a predetermined point. The

output of the float switch is used in mechatronic systems to specify different

liquid levels, such as cutting coolant, hydraulic oil, lubrication oil, etc.

The picture below shows the float switch and its interior.

Float switches are usually

of two types: vertical and horizontal float switches. A vertical float switch

is positioned at the top or bottom of a liquid tank, while a horizontal float

switch is fixed along the tank sidewall. The basic working principle for both

types of float switches is identical, but there are differences in their

construction. Sometimes, analog types of different liquid-level sensors are

also used, such as ultrasonic liquid-level sensors, optical liquid-level

sensors, hydrostatic liquid-level sensors, etc., to measure the liquid level

more precisely. However, the use of these liquid-level sensors with mechatronic

systems is limited.

Flow Switch:

A flow switch is a

contact-type digital sensor used to detect liquid flow through a pipeline.

There are usually two types of flow switches: Piston type and Shuttle type. The

picture below explains a piston-type flow switch and its interior.

The picture shows a

permanent magnet and a reed switch functioning inside a flow switch. In the

piston-type flow switch, the permanent magnet is attached to a piston, which

can move against spring tension. When fluid pressure is present in the inlet

line, both the piston and magnet move toward the inner side. A reed switch is

associated with the body (as shown in the picture) and activates or deactivates

with the movement of the permanent magnet. The output signal of a reed switch

can be either Normally Closed (NC) or Normally Open (NO), and it is considered an input signal for a mechatronic system. The basic working principle of a

Shuttle type flow switch is similar to that of a Piston type flow switch,

except a shuttle is used instead of a piston.

Flow Sensor:

A flow sensor

is an instrument capable of measuring the amount of liquid (usually water)

passing through an orifice. Different types of flow sensing technologies are

available, depending on the measurement techniques, such as Mechanical flow

meter, Ultrasonic flow meter, Magnetic flow meter, Thermal flow meter, etc. The

most common and cost-effective type is a mechanical flow meter, which measures

the flow by the rotation of a propeller or paddle-designed turbine wheel. The

rotor inside the flow sensor spins proportionally to the liquid flow and

generates pulses detected by a Hall effect sensor. By measuring the pulses per

second, the controller obtains information about the flow rate through the

orifice. The main disadvantage of using this type of flow meter is that it can

get clogged when the liquid is dirty or it may not function properly when the

water flow is too low. The picture below shows a turbine-type mechanical flow sensor

and its interior.

Temperature sensor:

The temperature sensor is

commonly used to measure the temperature or temperature changes of an object.

It is an analog-type sensor utilized in various applications such as

refrigerators, computers, motor control, processing industries, and

automobiles. There are three main types of temperature sensors: Thermistor,

Thermocouple, and Resistive Temperature Device (RTD), which are frequently

found in mechatronics systems. The output signal of the sensor is typically a

variable resistance or changing voltage, which is sometimes transmitted through

a suitable circuit.

Thermocouple - A

thermocouple is made by joining two different metals together, leaving one end

open (refer to the picture). The joined end is called the hot junction, while

the open end is known as the cold junction. When the hot junction is heated, a

small potential difference or voltage is generated between the terminals of the

cold junction. By measuring this voltage, a controller can determine the temperature

at the hot junction. The amount of voltage depends on the level of heating and

the properties of the thermocouple material. To obtain a proper sensing signal,

the voltage is passed through an amplifier and converter circuit, which makes

it compatible with the controller. Refer to the diagram below for a typical

thermocouple system.

Resistive Temperature Device

(RTD) - The resistive temperature device (RTD) operates based on the principle

that the electrical resistance of a metallic object changes with temperature.

It utilizes a length of metallic wire, typically made of platinum, as the

sensing element. As the temperature increases, the total resistance of the wire

changes, and this changing resistance is considered the output signal of the

RTD. Before applying the signal to the controller, it is passed through a

suitable circuit. RTDs are commonly used for extremely low and high-temperature

measurements. The diagram below illustrates how an RTD works.

Thermistor - The working

principle of a thermistor is similar to that of an RTD. However, instead of a

metallic wire, a polymer or ceramic material is used in a thermistor, making it

more cost-effective compared to an RTD. Most thermistors are of the negative

temperature coefficient (NTC) type, meaning their resistance decreases with

increasing temperature. Thermistors are suitable for low-temperature

measurements. The pictures below show a temperature sensor IC and an NTC

thermistor.

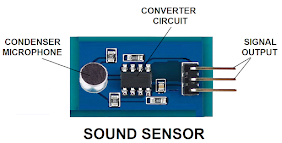

Sound sensor:

A sound sensor is a digital

sensor used to measure the intensity of sound or audio level. When the sound

reaches a certain threshold value, the sensor generates a signal voltage. It

consists of a small microphone that converts sound into an electrical signal

according to its intensity. The output signal from the microphone is sent to an

amplifier and then through a circuit to make it suitable for the controller. A

potentiometer is used with the sensor board to define the sound intensity at

which the sensor should act. Sound sensors are used in various applications,

including security systems, monitoring services, and switching applications.

Refer to the picture below for a sound sensor.

Light sensor:

A light sensor is an

analog-type sensor used to measure the intensity of light. It commonly employs

a silicon photodiode, which produces an analog voltage proportional to the

light intensity. Another type of light sensor is the Light Dependent Resistor (LDR),

which changes its resistance value based on the amount of light falling on it.

When no light is present, the resistance of the LDR is high, and as the light

intensity increases, the resistance decreases. The output of the LDR is usually

passed through a converter circuit to suit the requirements of the control

system. These sensors find applications in various fields, including the

machining industry, computers, and medical instruments. The pictures below show

an LDR and a light sensor.

Tilt sensor:

A tilt sensor is a digital

sensor used to detect the orientation or inclination of an object. It consists

of two conductive elements placed with a small gap inside a hollow glass

cylinder (refer to the picture). A small rolling ball or a mercury blob is present

inside the cylinder, which can easily slide. When the sensor is oriented in a

specific direction, the rolling ball or mercury blob makes contact between the

two conductive elements, acting as a switch and generating a sensing signal

output. In an inclined condition, the rolling ball or mercury blob moves away

from the conductive elements, disconnecting the switch. Tilt sensors are used

in mechatronics systems to secure a specific position. The picture below shows

a tilt sensor.

Touch Sensor:

Touch sensors are available

in two main types: resistive and capacitive. They are utilized with different

operating panels and control boards in mechatronics systems. Capacitive touch

sensors are more commonly used compared to resistive ones. A resistive touch

sensor is composed of two separate thin conductive layers, usually made of

Indium Tin Oxide, separated by a spacer with small spacing between them. A

flexible foil film is deposited over them. A small voltage is applied uniformly

to the conductive layers. When the surface screen of the sensor is pressed with

a finger or stylus, the upper conductive layer touches the lower one, causing a

voltage drop between them, which serves as the sensor's output signal. When the

pressure is released, the upper layer returns to its initial position. Refer to

the picture below for the functioning of a resistive touch sensor.

In a capacitive touch

sensor, a thin insulating cover is placed on a conductive coating material,

creating a sensing plate. The conductive coating plate acts as an electrode of

a capacitor, and the other electrode assumes to be the environment or human

finger. By applying a small voltage to the conductive plate, a parasitic

capacitor 'Co' is formed between the conductive plate, insulating cover, and

the surrounding environment (see the picture). When a finger touches the top

surface of the conductive plate, a new capacitance 'Cr' is created by the

conductive plate, insulating cover, and a human finger. The resulting difference

in capacitance can be recognized as the output of the touch sensor. The

following image illustrates the basic working principle of a capacitive touch

sensor.

Humidity sensor:

Humidity sensors are analog

sensors used to measure the presence of water vapor or moisture in the air or

gas. They play a vital role in selecting electrostatic components or operating

high-voltage devices. Among different humidity sensors, capacitive humidity

sensors are commonly used. These sensors utilize a hygroscopic dielectric

material placed between two electrodes. The dielectric material is often made

of plastic or polymer, with a dielectric constant ranging from 2 to 15. The

dielectric constant of water vapor is higher than that of plastic or polymer at

a standard temperature. When a humidity sensor is exposed to the atmosphere,

the sensor's dielectric material absorbs water vapor, leading to an increase in

capacitance. This change in capacitance is directly related to the moisture

present in the air. By measuring the capacitance value of the sensor, the

humidity or moisture level can be determined. A converter circuit is typically

used with these sensors to interface with the controller. The picture below

shows a humidity sensor and its sensing element.

Pressure or strain sensor:

When a force is applied to a

stationary object, it leads to two factors: stress and strain. Stress refers to

the internal resistance of the object, while strain represents the deformation.

A strain sensor or strain gauge is used to measure the deformation of an object

based on the applied force. A strain gauge contains a resistor whose resistance

value changes with the applied force. By measuring the resistance value, the

applied pressure can be determined. Strain gauges are utilized in mechatronics

systems to measure force, pressure, tension, and weight on a device. Different

shapes and designs of strain gauges are used based on the system's

requirements. The picture below shows a strain gauge and its working principle.

In a strain gauge, the total

resistance of a metallic wire depends on its length and cross-section. The wire

is typically arranged in a zigzag configuration on a springy board inside the

strain gauge (refer to the picture). When pressure is applied to the board, the

effective length and cross-section of the wire change, resulting in a change in

resistance. By measuring the changed resistance value, the applied impact on

the strain gauge can be determined. Since the resistance value obtained from a

strain gauge is usually very small, a Wheatstone Bridge and an amplifier circuit

are used to amplify the signal for the controller, making it measurable.

Linear Variable Differential

Transformer or LVDT:

The Linear Variable

Differential Transformer, or LVDT, is an analog sensor used to measure small

amounts of linear displacement, even up to a micron level, particularly for small

objects. It operates on the principle of mutual induction, generating the

necessary electrical signal based on the measurement. Inside an LVDT, a core

and three coils function as a transformer. The transformer comprises one

primary and two secondary coils, with the primary coil typically positioned in

the middle of the secondary coils (see picture below). The core, made of

magnetic material, smoothly glides inside the cylindrically wrapped coils. A

slender rod, usually made of non-magnetic material, is connected to the core

and the moving device. The image below displays an LVDT and its structural

details.

The resultant flux passes

through the core, inducing a voltage in the secondary windings. This induced

voltage changes in the secondary coils, displacing the core in either

direction. By measuring the induced voltage in the secondary coils, the

displacement of the equipment attached to the core can be measured.

Additionally, the phase of the induced voltage can be used to determine the

direction of the movement. LVDTs find application in various mechatronic

systems that require highly accurate or precise linear measurements.

Hall Sensor:

A Hall sensor is an analog

sensing device used to measure the strength of a magnetic field. It operates

based on the Hall effect principle. When a magnetic field is brought close to a

current-carrying conductor, oriented perpendicular to the electric field, a

potential difference is generated within that conductor (see picture). The

output voltage or potential difference from the sensor indicates the presence

of a magnetic field. The output of the Hall sensor is typically passed through

a suitable converter circuit to obtain the required signal for a controller.

This sensor can only detect either side of a magnetic pole. The left picture

below illustrates the Hall effect principle, while the right picture shows a

Hall sensor module.

Flex Sensor:

The flex sensor is also an

analog-type sensing device used to measure the curvature of an object,

indicating its flexibility. It is usually thin and flexible, and its resistance

value depends on the curvature of its surface. In a straight position, the

sensor has a fixed resistance, which changes based on the curvature. Since

mechatronic controllers can only interpret voltage variations as feedback, a

suitable voltage driver circuit is used in conjunction with the sensor to

obtain the desired signal voltage output. Occasionally, this type of sensor is

employed to detect finger movements in robotic arms. The image below depicts a

simple flex sensor.

Potentiometer:

At times, a potentiometer is

also employed as an analog sensor to determine the position of a moving object

or as a position sensor. Potentiometers can be of linear or rotary types, with

the type selected depending on the movement being measured. A shaft rotation or

slider movement alters the resistance of the potentiometer, allowing for the

measurement of the positional changes of a moving device by estimating the

corresponding resistance value. Since mechatronic controllers typically measure

voltage changes as feedback, a voltage driver circuit is commonly used with a

potentiometer to obtain the necessary voltage output. The images below depict a

linear potentiometer and a rotary potentiometer.

Smoke Sensor:

A smoke sensor is a digital

type sensor commonly found in places like hospitals, shopping malls, and

mechatronic systems. It detects the presence of smoke and gas, serving as an

indication of a potential fire source. Smoke sensors commonly work in two ways:

optical smoke sensing and ionization smoke sensing. Optical smoke sensing

relies on the principle of light scatter, while ionization smoke sensors

utilize an ionization system to detect the presence of molecules in the air,

generating a signal that is acceptable for a controller. The use of these sensors

is primarily limited to mechatronic systems. The image below illustrates a

smoke sensor.

Ultrasonic Sensor:

The working principle of an

ultrasonic sensor is similar to that of the sonar system used in ships. It is a

non-contact type digital sensor. In an ultrasonic sensor, a sending and

receiving transducer are housed within the same unit (see picture). Ultrasonic

sound is transmitted from the sending transducer and returns to the receiving

transducer, allowing for the determination of the position of an object by

analyzing the reflected signal. Ultrasonic sensors can detect materials such as

metal, wood, concrete, rubber, and glass. However, materials like clothes,

cotton, and wool are not detected as they absorb ultrasonic waves. These

sensors are utilized in various mechatronic systems, including object counting,

liquid-level sensing, automatic doors, and robotic systems. The image below

displays a complete ultrasonic sensor module.

Motion Sensor:

A motion sensor is a

non-contact digital sensor commonly employed in security systems and

mechatronic systems. There are three fundamental types of motion sensors:

Passive Infrared Sensor (PIR), Microwave Sensor, and Dual-Tech Hybrid Sensor.

Among these, PIR sensors are primarily used in security systems. A PIR sensor

typically consists of a pyroelectric sensor as the sensing element, covered by

a Fresnel lens. The pyroelectric sensor contains a small layer of lithium

tantalite sandwiched between two conductors, created through a doping process.

It detects the infrared radiation emitted by the human body and generates a small

signal. These sensors are accompanied by an amplifier circuit to obtain the

required feedback for the controller. A Fresnel lens, a typical design lens

cover, is used to protect the pyroelectric sensing element, allowing the

accumulation and focusing of the infrared radiation arriving at the sensor. The

sensing range of these sensors varies from 8 to 10 meters. When a human or

other animal enters the sensing area, the emitted infrared radiation activates

the PIR sensor, generating an appropriate signal for the controller. This

signal can be used to trigger an alarm system or initiate video recording. The

image below shows a passive infrared sensor.

Micro-Electro-Mechanical

System or MEMS:

A Micro-Electro-Mechanical

System, or MEMS, is an electro-mechanical device typically integrated onto a

single silicon substrate. It incorporates micro-sensors, micro-actuators, and

other electronic circuits. Some MEMS devices utilize tiny movable contacts. The

components in MEMS devices are usually miniature and assembled in a compact

structure within a single casing. MEMS devices can be made with ceramic,

plastic, or metallic packaging. Different types of MEMS sensors are used in

mechatronic systems, automobiles, and mobile phones. The most commonly used

MEMS sensors include accelerometers, gyroscopes, and magnetic field sensors.

The image below displays a MEMS board and its components. MEMS devices

typically generate multiple electrical signals. For instance, a MEMS

accelerometer can measure static or dynamic forces resulting from acceleration.

A gyroscope can measure changes in angular positions, and a magnetic field

sensor can precisely measure incoming magnetic fields. The image below shows

three sensors: an accelerometer, gyroscope, and magnetic field sensor

integrated within a standard architecture.